By Stephen Hayes, Managing Director, Beckhoff Automation UK

For many manufacturers, the first steps to digitalisation are often wrought with uncertainty: “What network architecture will work best? What controllers, hubs and switches do we need?” and “How do we build a system with real-time communication?”

For many, going back to basics – and considering the underlying fieldbus technology that most of today’s digital platforms are built on – is perhaps the best first step.

It doesn’t matter whether a company runs dozens of pick and place robots or has advanced motion control systems in place, the reality is that all companies want the same thing – to run efficient, robust and often scaleable networks that can handle increasing high-volume processes that are digitally connected.

Smart factories

There’s a lot of talk today of smart factories and its features that include remote monitoring, predictive maintenance and real-time motion control. Many manufacturers have already committed to installing such systems in place, but are now facing challenges, including complex system architectures, hardware miniaturisation, the blurring lines between ERP (enterprise resource planning) and MES (manufacturing execution planning), and the need for additional hardware such as switches, hubs and network cards to make it all seamless. But rather than increase complexity straight away, it’s advisable for business leaders and engineers to go back to basics and first consider their network from the physical, field level. Whilst fieldbus and industrial Ethernet-based systems have been around for many years, the best ones are those that have been continually and openly developed to keep up to date with the advanced needs of today’s modern, digital applications.

EtherCAT

EtherCAT is the best example of this. Introduced by Beckhoff in 2003, EtherCAT is a high-performance, low-cost Industrial Ethernet that has evolved to become a globally recognised, open international standard that continues to be developed by the EtherCAT Technology Group (ETG).

What makes EtherCAT special is that, whilst it uses the same low-cost hardware and cabling systems of the established Ethernet technology, it replaces the traditional TCP/IP technology stack with a real-time system that’s one of the fastest, most robust Ethernet platforms on the market today.

In a network made up of a central controller (a master) connected to a series of drives or nodes (slaves), a data signal would typically be transmitted and received to and from each node, being processed by the CPU and returned to the controller. This process uses large bandwidth as multiple frames of data need to be sent, received and processed. It’s also slow, as data is processed through each layer of the technology stack. EtherCAT solves this problem by taking a different approach.

With EtherCAT, a single Ethernet telegram, or frame, is enough to send and receive control data to and from each node. This way, each node reads the data addressed to it and writes it back to the frame in real time as the frame moves downstream. The result is a deterministic, synchronous, real-time system that increases the data rate to over 90%. Combined with Ethernet’s duplex feature, which allows signals to be sent and received simultaneously, this means the effective data rate can exceed 100Mbit/s.

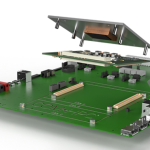

This master-slave relationship also allows EtherCAT to be networked in any topology, whether line, tree, star or ring. Where engineers may have traditionally cascaded field devices using switches and hubs, these are now integrated into EtherCAT’s I/O modules; this means they can be eliminated entirely, further reducing the infrastructure costs.

These combined features mean EtherCAT can process 1000 I/O points in 30µs and communicate with 100 servo axes in 100µs, with a single Ethernet frame being capable of exchanging the equivalent of almost 12,000 digital inputs and outputs.

EtherCAT setup

Example

The development of accurate and powerful machine vision in industrial automation applications has been challenging. On the one hand, machine vision systems applications are frequently expected to process only comparable products. In these cases, the identification software can be less complex as the input is predictable – because products on the line are likely to be similar. However, on the other hand, identification must be 100% accurate and performed within seconds – errors in a factory setting are entirely unacceptable.

The stringent requirements of speed and accuracy in industry limits the processing time available to the identification software, potentially causing errors. Such events may result in costly line stoppages, potential recalls and could be dangerous, depending on the products in question.

A modern approach is to use neural networking in the software, otherwise known as machine learning. Rather than trying to predict and code what a product will look like into the software, the program is instead designed to categorise what it sees. The machine-learning software is trained with numerous examples of ideal products, in every possible configuration, to slowly build a descriptive dataset. As a result, the machine learns the difference between an ideal product and a defective one.

When properly trained, these systems can quickly and continuously sort products faster, more accurately and safer than would otherwise be achieved by hand or more computationally intensive approaches.

It is also vital that operators maintain the highest levels of accuracy whilst ensuring their throughput targets are met. To achieve this, communication between all aspects of the system — from the camera and picking equipment to the conveyor and connecting buses — should be as fast as possible.

Some machine vision developers approach this problem by designing all of the components into one modular, drop-in product. By keeping everything from the lighting, camera and software under one lid, the aim is to have a fast and accurate product that can be easily retrofitted into existing systems.

Beckhoff’s specifically designed TwinCAT Vision slots perfectly into existing TwinCAT universal control systems. Latency is further eliminated through EtherCAT fieldbuses and cables, whilst synchronisation of components is assured by the governing runtime software. All this information is fed through a Windows-based graphical interface to make programming and troubleshooting easy.

With this solid hardware foundation, it’s possible to achieve unparalleled input flexibility. Potentially any sensor, such as infra-red and hyperspectral detectors, can be mapped into the software, and the neural networks trained to adapt. This flexibility meets the needs of almost any machine vision system — no matter how bespoke or unusual.

Important for manufacturers

So, for most manufacturers adopting such standards means they are able to level the digital playing field. If you’re a robot manufacturer, for example, EtherCAT could, in effect, let your controller combine fieldbus functions for your HMI, vision system and simulation software without the need for additional hardware.

Whilst the first steps to digitalisation may seem wrought with challenges, this isn’t always the case. Having found the most suitable fieldbus for your needs, you can begin to answer some of the original questions and even ask more interesting ones like: “How big can we go?”