In the 2016 Mexican Grand Prix, Valtteri Bottas took the record for the highest speed in a Formula 1 race, hitting 231.4mph. Reaching these high speeds requires intensive testing before racers even start to hit the track. So, is there room for remote monitoring in optimising a car for racing performance?

In the highly-competitive world of Formula 1, it is crucial that a racing team’s pit crew are fully aware of any problems that may affect the car’s speed, performance and safety. One efficient way to achieve this is with telemetry, or remote monitoring technology, where sensors throughout the vehicle collect data and share it wirelessly with the pit crew via a transmitter.

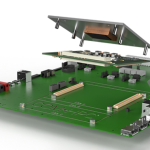

One such transmitter is T24, with modules for inputs like strain, temperature, voltage, and more. For example, the strain gauge sensor transmitter module has a wireless range to 800m in the open, with up to 200 updates per second.

Maximising traction

The car’s traction also greatly affects racing performance, especially when the car turns, where stability is crucial. Positive or negative camber to a wheel will angle the tyre, even when the vehicle is going straight. When the car goes into a corner, the resulting forces push its entire weight onto the tyre, allowing higher speed around the corner without losing traction.

Many racing teams measure camber by hand and with separate tools, but this can be time-consuming and unreliable. Therefore, one racing team approached Mantracourt to provide fast and precise solution for testing weight and incline. The result was a wireless solution that connects the car’s sensors with software. The team used inclinometer sensors and 0-10V voltage transmission modules to measure the incline at different angles. To find out the weight each wheel could tolerate, Mantracourt used the T24 wireless strain gauge transmitter module. Such a module enables high accuracy wireless measurement of signals from bridge-based transducers like load cells and pressure sensors. After collecting data, the team used Mantracourt’s T24 integrated logging and viewing software to check the car’s centre of gravity, which determined whether the weight of the car was distributed properly on each wheel.

With wireless technology, the racing team converted voltage readings from sensors to engineering values – i.e, high-precision readings, allowing them to make fine adjustments to the angle and weight distribution of the vehicle for optimal performance. The racing team can now test track performance and make small adjustments based on the driver’s feedback.

Measuring torque

The accurate measurement of torque in a rotating system for a racing car can be challenging. However, Mantracourt used the T24 to monitor torque for the University of Quebec’s Ecole de Technologie Superieure Formula SAE race team entering the international engineering student competition.

The race team had designed a new differential assembly for their prototype car and, whilst theoretical calculations had predicted positive results for performance, it could only further develop it with data acquisition and validation. Furthermore, the behaviour of the system needed to be monitored, because several discrepancies emerged during the driving tests.

Typical strain gauge installation to the driveshaft to measure the torque was not an option because of the rotating shaft. The shape and size of the car’s rear was also a problem, not making it easy to install a standard monitoring system. Since the team was on a tight budget and deadline, this excluded a bespoke solution. Hence, strain gauges were installed onto each driveshaft, and then connected to the T24. The team also installed a short cylinder to hold the transmitter and the battery. Then, a T24-AO1 wireless receiver was added on a bracket near the transmitter for best signal integrity; this was connected to the car’s data acquisition system. A calibration was conducted with a known load in a static situation, using Mantracourt configuration software.

The solution helped the Formula SAE ÉTS team achieve considerable success in several international competitions, securing first and third place against fierce competition.

Preventing water leakage and wind noise

For a different automotive racing team, wireless technology was used to improve the accuracy of the door seal gap measurement to prevent water leakage and wind noise in the vehicle. Limiting wind noise is of utmost importance for the safety of the driver, as the cockpit of a race car is known to be one of the noisiest environments around, due to wind noise and 140Db engine.

Previously, the measurement of the door seal gap area was performed with time-consuming tools and specialist methods. The automotive OEM wanted a faster measurement system that was capable of measuring the door seal gaps between two adjoining panels, with instant visual feedback of the data, which could then be stored digitally for further analysis and improvements.

The OEM used the WISEgap system, incorporated with the T24 wireless telemetry technology. This is a sensor-controlled wireless gap measurement system, allowing multiple modes of measurements: static, real-time dynamic and high-speed dynamic. The flexible nature of the WISEgap system with T24 meant that the OEM could and work across all the different models and closures for the calibration. Using this system improved accuracy and time savings for their setup and measurements. What once took two hours per door now takes five minutes. By wirelessly measuring door seal gaps, the motor team was able to prevent water leakage and wind noise issues in all stages of production, as well as conduct analysis and testing on the car that was previously challenging.

By Robert Badcock, CEO, Mantracourt