By Jeff Elliott, California-based technical writer

Integrated passive components (IPCs) are attracting increasing interest due to the miniaturisation of wireless devices, as well as the need to increase reliability of signal conditioning in RF circuits such as filtering, impedance matching, differential-to-single-ended conversion and coupling.

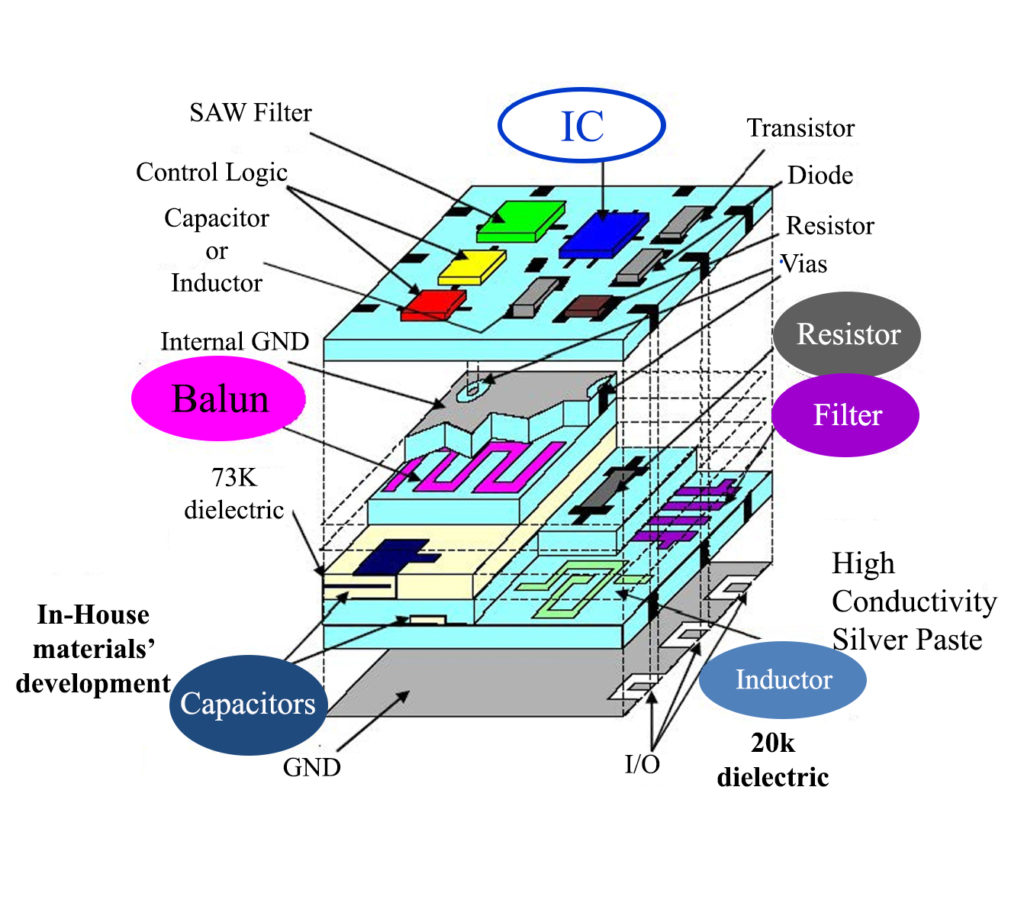

IPCs are essentially electronic sub-systems that combine multiple discrete passive components into a single surface-mounted device. Manufactured using low temperature cofired ceramic (LTCC) technology that allows passive components to be layered “three-dimensionally”, IPCs deliver the same functionality as 10-40 individual components, whilst dramatically reducing board space. With this approach, the entire front-end between RF chipset and antenna can be manufactured in a single, ultra-low profile (0.35-1.0mm total thickness) package that’s less than 20% the total size of the same circuit comprised of discrete components; see Figure 1.

“If you were to look at the circuit from above, you would only see three chips: the RF wireless chip, the IPC and the antenna,” says Manuel Carmona of Johanson Technology, maker of high-frequency ceramic components including chip antennas, high-Q capacitors and EMI chip filters. “The design is very clean and really small. You can make the overall PCB size much smaller using IPCs whilst maintaining high wireless performance.”

Industries already adopting IPC technology include automotive, medical, mobile electronics and “smart” wearables.

Reliability

For customers less concerned with board space or overall size, IPCs deliver another significant benefit – greater reliability. By creating a circuit within a small LTCC package, variability and potential points of failure are all but eliminated when compared to mounting many discrete components. A single integrated package of matching components also assures compliance with FCC or ETSI requirements.

“A lot of the variability of ‘solo’ surface-mounted components is due to the individual variance of each component. When you multiple that by 10 to 20 components, you just need one weak link in the RF chain for the entire front-end to fail,” says Carmona.

Carmona states that IPCs are available for almost any type of passive circuit, including low- and high-pass filters, diplexers, triplexers, impedance-matched baluns, balun-filters band-pass filters, couplers and other custom signal-conditioning circuits; see Figure 2.

LTCC technology

The process to manufacture IPCs is similar to the technology used to create multi-layer SMD component parts, such as capacitors and inductors. However, low temperature co-fired ceramic (LTCC) manufacturing allows circuits to be embedded in as many as 40 separate layers in a three-dimensional package that is still very low profile.

Using this manufacturing process, Johanson Technology has developed a line of small, highly-reliable IPCs for RF systems manufactured with a proprietary LTCC process. These components operate over several bands from 300MHz to 10GHz, covering cellular, DECT, WLAN, Bluetooth, 802.11 (a, b and g) and GPS applications.

Each integrated package is thoroughly 100% RF-tested to ensure all components are working properly and integrate together.

“Because of the LTCC manufacturing process is extremely precise and repeatable, we can stay within the manufacturing limits of alignment, variations, and so forth, so you get really consistent, robust, RF circuitry,” says Carmona.

As a result, Johanson Technology guarantees the RF sub-system to pass its RF performance requirements with FCC and ETSI and any other emission regulation.

Match-filter baluns

One standout IPC offering is Johanson Technology’s line of matched-filter baluns. A balun is an electrical device that converts between a balanced (differential) and unbalanced (single-ended) signal. The component can take many forms and may include devices that also transform impedances.

Because many RF wireless chipsets have differential (two pins) outputs – an RF input and output – that connect to a single-ended antenna, the signal needs to be converted from differential to single-ended in a specific impedance ratio. Most of the time, these wireless RFICs have a non-standard complex impedance which the IPC’s match for optimum power efficiency. Some baluns are also combined with a bandpass, low-pass, or high-pass filters.

To accomplish an impedance conjugate match, Johanson Technology works with chipset OEMs to create a specific match-filter baluns with a matching part number for each chip. The collaboration begins with reference designs during development to simplify and speed-up adoption of the chipset in the market.

“The IPC is basically a plug-and-play solution,” says Carmona. “By working with the leading chipset manufacturers, we have already completed the R&D to ensure it is optimised for that specific chip. Not only will it work, but it will comply with any emission requirements.”

Markets

Because IPCs require much less board space, smaller miniaturised devices with RF circuitry can be designed and smaller form-factor products created.

“With PCB real estate at a prime, the size and placement of the passive components are critical because, as everything gets smaller, it becomes increasingly difficult to place more components on the board,” says Carmona. “Therefore, design engineers are looking to component manufacturers to deliver miniaturised solutions that occupy next to no real board space.”

Beyond size, a smaller PCB can also impact the aesthetics of a product, allowing for slim, low profiles. The elimination of components on a 10:1 or greater basis also reduces the overall weight of devices, even if that saving is measured in tenths of grams.

These factors have major implications for next-generation smart wearables (rings, bracelets, shoes, jeans, shirts and other apparel), implantable medical devices and portable electronics. As it relates to greater reliability, Carmona says the automotive industry is already using IPCs for on-board cellular, Wi-Fi, Bluetooth, satellite radio and GPS systems, as well as key fobs. Hence, IPCs are designed to meet AEC-Q200 standards