By Greg Lynch, Automotive Business Development Manager, TR Fastenings

The automotive industry is a vital part of the UK economy, with a £82bn turnover, and another £20.2bn in value-added products and services. There are over 30 vehicle manufacturers in the UK and some 2,600 automotive component manufacturers − a single car has around 30,000 parts.

The automotive industry has a traditional tiered supply chain − Tiers 1, 2 and 3, with Tier 1 feeding directly into OEMs. But, some lower-tier component manufacturers, such as TR Fastenings (TR), are challenging this structure, taking a much larger role in innovation and Tier-1 production-line support.

Project background

Faltec Europe required a bespoke fastening for a new major programme it had secured with a key global OEM. The trim product to be developed was an injection-moulded exterior trim part for a new vehicle due for release in November 2019.

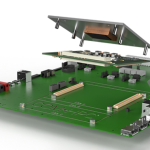

A late design change to improve the fit of the part to the vehicle required attaching a strengthening support via a peel type rivet. Peel rivets are a type of blind rivet designed to offer improved support in brittle, soft or ductile materials, applicable to the vehicle trim products in this project.

Using bespoke tooling, the head of the Peel rivets explode and become mushroom-shaped as they enter the moulding. This creates a large blindside-bearing surface, significantly reducing the risk of the rivet sinking into the moulding or breaking it.

Since TR and Faltec are both part of the North East Automotive Alliance (NEAA) network, TR was appointed by Faltec as its provider of the fasteners and tooling.

“Being an active member of the NEAA has enabled good business networking opportunities with new and existing customers,” said Greg Lynch, Automotive Business Development Manager at TR.

Not only could TR provide the specific fastener solution, but in this instance, it was also able to supply bespoke tooling compatible for the fastener. The tooling required a bespoke rivet gun that would not only automatically fire the rivets into the moulding to be joined, but also have capability to apply rivets in a fast production environment.

Project challenges

Timescales were challenging for both parties but, with close co-operation, qualified parts were supplied along with the tooling for development and ongoing production, with both being delivered on time. Not only did TR have to supply production intent rivets in a short timescale but, also, the gun was ordered late due to last-minute design changes, requiring a 24-hour delivery. This late design change by the OEM required special rapid response by TR and Faltec. TR was able to take the lead on supplying fast-production intent rivets and tooling in a very short time.

“Perhaps the biggest challenge came with technical advice and training. TR had to ensure correct and safe operation of the rivet gun. Due to its bespoke nature, Faltec staff responsible for the operation had no experience in the use of this particular tool and engineering,” said Lynch.

A TR’s quality manager visited Faltec’s production facility to help with the layout process and to demonstrate the rivet tool’s use in a safe manner. Since full service was of the utmost importance to TR, its engineers visited Faltec several times, to explain how the rivet gun operates and to train staff in its appropriate use and safety. TR continued to provide support throughout the trial phase, and it assisted in the technical evaluation for onsite production.

“Following late design changes on this project, Faltec Europe was faced with a challenging timeline to find a solution. We contacted TR for its input and support, which proved invaluable. TR quickly offered a product that met the design requirements and they also suggested solutions on the assembly equipment that could be used, speeding up our process development. The final result was a change delivered on time and on budget,” said Wayne Turnbull, Senior Manager at Faltec Europe.

Project outcomes and advantages

Following the success of this project, TR will now supply serial production to Faltec, further cementing their relationship.

Outcomes and advantages of the project included:

- Parts and tooling were delivered to specification and on time, given the challenging timescales.

- TR supplied Faltec with additional product tooling over and above the initial bespoke fastening request for quotation.

- TR provided ongoing project support ensuring onsite production timescales were met.

- The successful project has resulted in ongoing work for TR for the supply of serial production for a further three years.

“Providing a first-class service and gaining trust from Faltec Europe was of paramount importance to us,” said Lynch.