In 2021 almost 356,000 new e-vehicles were registered in Germany, setting a new record. In addition, the first automated drive systems have already entered the European roads. For example, the Drive Pilot in the new Mercedes S-class controls the car up to 60km/h, which meets the requirements of level 3 of autonomous driving.

But, alternative drives and AI-based control also pose new challenges to the automotive industry. For example, cable harness development is undergoing major changes, and few or no automated process steps and the classical silo mentality in product development no longer meet the needs of future developments of high-voltage harnesses, that must include thermal, electrical and electromagnetic simulations, and for essential redundancies and modified standards such as ISO 26262.

Growing complexities

E-mobility and automated driving systems are changing the design of cable harnesses from the ground up, linking multi-voltage electrical systems and intelligent network topologies and more complex controllers, among the many other technical developments. With the growing system complexities, mutually dependent subsectors such as wiring, geometry, components, systems and software are interacting with one another more than ever before. In turn this requires 3D and configuration data models with detailed simulations. This also means that the common, document-based procedures can no longer meet the more complex demands of simulations, since they been originally designed for isolated processes. Also, when data is transferred manually, errors are easily introduced, and the impact of specific changes on production costs or functional safety can be costly due to the many interdependencies.

When coordinating many systems, not only that mistakes are easy to make, but, also, if any changes are made at the geometry level, their impact on other components, such as wiring or EMC management, are not immediately obvious, and the ultimate production costs can only be conjecture.

For efficient and targeted development, it is essential that changes are calculated quickly and communicated between the individual disciplines, that simulations and validations are seamlessly incorporated into the process, and that comprehensive application and product life cycle management systems are integrated. For cable harnesses in particular, the development must distance itself from the document-based approach, which requires quite a few manual steps and a complicated data exchange between different systems and formats. Only a model-based approach can properly link the subsectors and facilitate a transparent development process.

Generative development with a digital twin

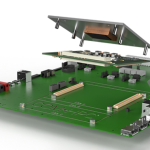

Companies such as SmartCable are now increasingly developing model-based tool chains to meet the complex development processes in a seamless, easier and more error-free way. With the aid of a digital twin that can grow alongside the product development, all subsectors can easily be accessed and interlinked, for a completely interdisciplinary approach. The entire process remains transparent and generative – from the first draft of the cable harness architecture to the final manufacturing information.

SmartCable’s tool chain works on the basis of a cross-discipline data model that is a digital twin of the actual cable harness. The model grows dynamically as the development advances. Via interfaces designed for their respective subsectors – so-called “views” – all participants, such as designers or manufacturing planners, can access the central model, which can be drawings, drafts, 3D topologies, simulations and configuration files. Via the data model, every point of the 3D topology refers to the respective counterpart in the cable harness drawing and its scaled formboard drawing.

Since modifications in any one subsector are not manually transferred to another subsector but generatively factored into the central 3D data model, the error rates decrease, and changes can easily be traced at any stage. If the 3D model is modified, the effects on the electromagnetic and thermal compatibility or the ultimate manufacturing costs can be determined automatically. There are individual rule catalogues that can be expanded as needed and which serve as the basis for the algorithm to check the conformity of the various development steps with standards and quality requirements, such as those specified by the OEM or by regulation. Simulations that are essential to e-mobility and autonomous driving can also be directly derived from the central data model without any manual preparation, saving valuable development time and reducing the time-to-market, but also facilitating thorough cost control.

Scaleable software

Technological advances require agility, which means that the respective software components must flexibly adapt to new circumstances. To enable a high degree of scaleability, our generative tool chain uses a CAD platform and a data model with no size restrictions. We have been working closely with CAD designer Dassault Systèmes to achieve this. Solutions are therefore directly integrated into the CATIA development environment commonly used in this sector, instead of cumbersome imports via external interfaces.

Another helpful tool is the specially-designed Engineering Knowledge Base, which serves as the foundation for automating validation and testing in the design process. The patented process provides engineering know-how, such that algorithms can make decisions based on it. Thus, SmartCable emulates the procedure applied by an experienced designer, eliminating many manual steps and significantly shortening the overall development time.

By Uwe Prüfer, Head of Research and Development, SmartCable