As we continue our investigation into 8-bit microprocessors, this month’s column focuses on their integral role in driving innovation in industrial applications.

Across the industrial sector, widespread electrification and digitisation are transforming a wide array of operations and processes. Traditional factories and production plants are a significant part of this segment, where automation and robotics play a crucial role in enhancing efficiency and productivity. However, the industrial sector also includes a diverse range of other facilities, including offices, distribution hubs, and research facilities.

Modern industrial organisations increasingly rely on digital technologies for functions like remote monitoring, predictive maintenance, and energy management. For instance, advanced sensors and data analytics are typically employed to optimise production processes, monitor equipment performance, and detect potential issues in real time. Additionally, the industrial sector is adopting advanced overarching solutions like the Industrial Internet of Things (IIoT) and artificial intelligence (AI), which rely on intelligent systems.

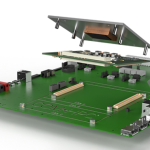

But with such diverse applications, the industrial sector necessitates tailored solutions to meet its specific needs, driving the demand for innovative intelligent technologies and digital solutions. Just like in the automotive industry, industrial systems also exhibit incredible scale and complexity. This demands the creation of architectures that rely on vast networks of interconnected but individual modules—rather than a singular system—to handle the required functionality.

As an illustration, let’s consider a scenario where a production line comprises numerous automation and safety elements as well as sensor nodes distributed across the entire building. These elements are responsible for continuous safe operation and need to be managed in real time with the data collected and processed before being relayed back to a central control unit. By employing this architecture, the complexity is significantly reduced and scalability is greatly improved, enabling the creation of large-scale industrial solutions. To fulfil the functionality of this system, each edge sensor node must have its own microcontroller unit (MCU). These can provide intelligent operation at the edge while seamlessly communicating vital information between the sensors and overall control systems as required.

In large-scale industrial applications, the advantage of using a networked approach with an MCU in the edge node goes beyond reducing the workload of the central processor. It also allows for better optimisation of data transfer over the network. By having each node controlled by a single MCU, data can be processed and filtered at the edge before being sent to the central processor. This intelligent data reduction significantly reduces the amount of data that needs to be transferred, resulting in improved network efficiency.

For engineers, the challenge in designing these systems lies in the sheer scale of industrial settings. With potentially thousands of individual modules within a single building, the cost and complexity of operating such a system can quickly become overwhelming, leading to increased production and maintenance costs. This is where 8-bit MCUs can prove to be invaluable. Unlike their more powerful and complex counterparts, 8-bit MCUs are better suited to provide exactly the functionality required for the task at hand; as with any project, the last thing you want to do is pay for unnecessary functionality. Such 8-bit MCU solutions help to minimise redundant overheads, resulting in more streamlined and cost-effective solutions.

With a single 8-bit MCU, the savings might be minor; but in the context of large-scale industrial applications, the combined reductions that 8-bit MCUs enable are exponentially magnified. They allow for the deployment of numerous nodes without incurring excessive costs or power consumption. The principle of ‘less is more’ also offers advantages for the ongoing maintenance, diagnostics, and fault-finding processes. Subsystems that are broken down and utilise straightforward yet efficient 8-bit MCUs are theoretically easier to handle compared with larger centralised systems that rely on more advanced control networks.

But not all 8-bit MCUs are made equally. When choosing microcontrollers for industrial applications, it is important to consider various key design requirements, such as speed, complexity, peripherals, and flash memory, in relation to your design. Given an 8-bit MCU within an industrial setting could be installed with systems ranging from production-line automations to office heating, ventilation, and air conditioning (HVAC), engineers need a wide range of options and careful selection to optimise their design.

This is something Microchip Technology engineers have kept in mind when developing the company’s . The company’s product range encompasses a wide array of solutions, catering to the unique industrial requirements of its customers’ applications. This includes rugged and reliable 8-bit solutions tailored for industrial settings, as well as devices like the innovative , which meets IEC 60730 Class B library (UL certified) and ISO 26262 FMEDA functional safety.

Industrial design is far from being a straightforward field: The term itself encompasses a wide array of sectors, systems, and functions, illustrating the discipline’s complexity. While engineers working on industrial demands may have wildly different priorities and considerations, there are still many shared factors. Achieving goals like simplifying the system’s architecture, reducing energy consumption, and lowering costs is a top priority for all engineers, and to accomplish these objectives, many engineers will rely on 8-bit MCUs, especially as their designs expand and they require distributed intelligence.

By Mark Patrick, Director Technical Content EMEA, Mouser Electronics