By Michael Garry, Amada Miyachi Europe

A growing trend in preventative health is wearable technology, like smart watches and monitors that are placed on the skin. The engineers of these devices must find solutions to make medical technology flexible and durable enough to work on a person’s wrist or hip, for example. Under-the-skin devices like replacement heart valves or neurological implants, on the other hand, receive Class III designation, meaning they are determined to be high risk as part of the CE marking process. These devices – usually tasked with supporting or sustaining human life – both offer more but also pose a greater threat to patients through device failure or incidental harm. At the same time, if materials inside the device leach into the body, they could cause infection.

Among other features, these devices require 100% hermeticity and joint integrity; see Figure 1 below.

Figure 1: Laser welding pacemaker cases creates hermetic seal

Quality care

Of course, the quality of a device is subject to a variety of factors, from its materials and design to the reliability of its manufacturing process and cost. For engineers working to enable quality care by manufacturing top quality devices, the manufacturing process must produce consistent quality at the most time- and cost-effective rate possible. For both Class III device manufacturing and the development of wearables, incorporating the right welding and bonding technology can facilitate high quality products whilst safeguarding patients’ wellbeing and protecting the manufacturers’ bottom line.

Take the task of seam welding, an important step to ensure hermeticity and device lifetime for such critical devices as pacemakers. Device manufacturers have no shortage of options. Plasma welding is often used and works relatively well. Electron beam welding is another clean process that yields relatively good results. However, each of these processes can consume time at needless rates. They also require highly complex systems with components like vacuum chambers. The more elements of a process involved, the more opportunities for problems to affect quality. Even if slight inconsistencies are spotted and remedied in a factory before being introduced into medical care, deficiencies can cause waste of material and time.

Legacy processes

Laser welding generally provides an equal or greater accuracy to these legacy processes and offers important advantages to manufacturers. First, no time-consuming vacuum chamber or similar is involved. Laser welding can be done in an inert gas atmosphere, generally nitrogen-based, as in Amada Miyachi Glovebox systems. Importantly, laser welding is usually quicker than its counterparts and creates very reliable joints. Generally, medical device manufacturers now opt for automated laser welding as a way of driving costs down and improving welding process control.

Advanced laser welding systems benefit from features like vision systems, which enhance automation capabilities on machines by interacting with the specific parts being welded. Vision systems use cameras to recognise parts, identify the weld areas and locate the optimal position for the laser to begin joining parts. This can save significant resources.

Many pacemaker parts are pressed, not machined, so the location of the interface varies. Manual alignment can take several minutes for each device. Vision systems and bespoke software algorithms on welding systems cut the task down to a few seconds.

Another major advantage of using laser is its flexibility. A prime example comes from the production of hypotubes. The process requires micromachining features into a tube, also known as a catheter tip. The tip is then welded to another wire or tube known as the hub. With an Amada Miyachi Laser Welding System, laser machines can both cut and weld the metal. In fact, standalone systems can perform marking and ablation of coatings, too.

Welding systems

In addition to welding together parts of pacemakers and hypotubes, laser welding systems are effective at welding certain types of stents, drug pumps, implantable valves and other life-supporting devices. It is not, however, necessary to use laser welding as a process for every invasive device, or even for every joint in the device.

To weld the batteries inside pacemakers for example, resistance welding is commonly employed. The most central way in which this process differs from laser welding is the relationship between the machine and the device being manufactured. In resistance welding, the welder comes into contact with the parts that are being welded together and applies pressure and current at that point. In laser welding, only the laser beam touches the area of the weld.

In the wearables market, however, the goal of joining parts together is not necessarily about seamlessness. Nonetheless, the reality of the human body and its interface with a device still poses a central challenge to manufacturers. A major question is how to integrate high technology – with its metalised circuitry – into items that flex with the patient’s form.

Here, the relevant technology employed is in some ways similar to resistance welding. Hot bar bonding uses a thermode (or Hot Bar) to create an electrical interconnection between materials under controlled pressure. The small, flexible characteristics patients expect from wearables can be achieved by forcing layers of material together in this way, like gold to monitor heart rate from contact with the skin and tiny flexible batteries to power the device.

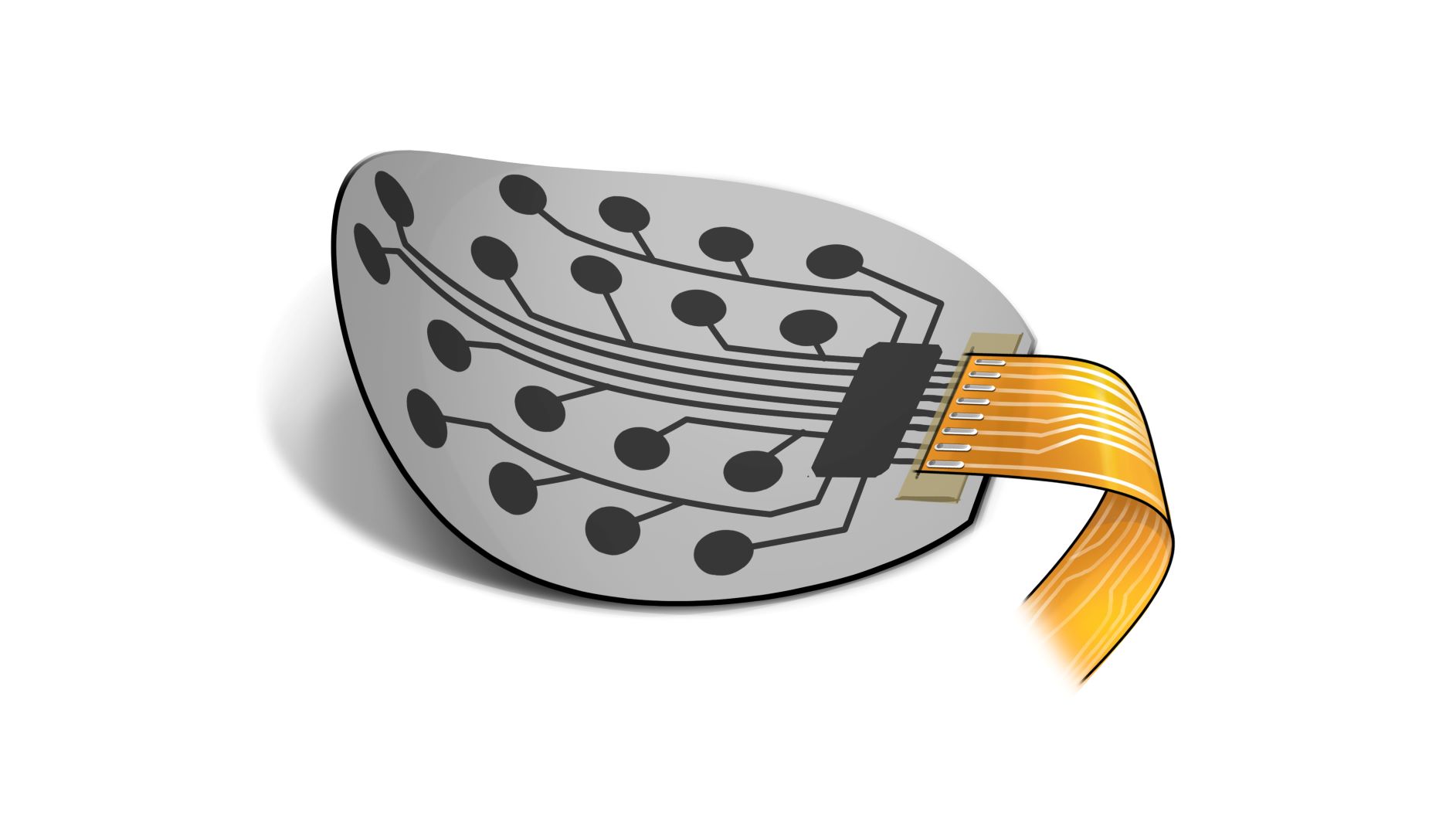

Figure 2: ACF bonding connects rigid and flexible circuit boards

Bonding types

Not all the elements bonded into wearables are forced to melt and reform. Anisotropic Conductive Film, or ACF, is a laminating or pre-bonding layer used when a fine pitch is required and where selective reflow soldering cannot be applied; see Figure 2. This facilitates interconnection between flexible circuit boards and displays, for example.

The ACF material consists of adhesive filled with conductive particles and a protective layer. The ACF is positioned over the bond surface, and the ACF laminating is achieved by applying temperature and pressure. Once ACF laminating is completed and the flex aligned to match the traces on the substrate, the thermode is again actuated to heat the parts to final bonding temperature under controlled pressure as the last step.

ACF bonding is one of several Hot Bar techniques. Others include Hot-Bar reflow soldering where two parts are coated with solder before it is melted to connect them; and heat staking, a pulsed heat process to join a plastic part with another plastic- or different-material part to form a rivetted type of joint.

Careful engineering

Of course, every application of these technologies requires careful engineering. It is best to consult with experts when developing product manufacturing programs that use advanced welding or bonding techniques.

Incorrect integration of laser welders may cause system damage. This may easily be avoided when working with suppliers that possess the necessary expert design and application knowledge. Furthermore, it is not always immediately clear which technology would best serve a medical device’s welding challenges, as the joint configuration is the key to choosing the correct welding process.

Device manufacturers have many welding and bonding technologies to choose from when engineering their manufacturing processes. Some technologies are best applied to Class III devices, and others to wearables and other non-invasive technology. In each case, it is crucial to understand the benefits and drawbacks of the technologies that perform similar functions when making decisions.