By Christian Schäfer, Director Electrical and Electronic Systems, Aptiv Mobility Architecture Group

Today’s electrical and electronic (E/E) architectures are not sufficient for the high bandwidths and redundancy requirements of future automated and autonomous driving. Autonomous vehicles are information-rich and increasingly defined by software that generates enormous amounts of data to train artificially intelligent (AI) algorithms – all fundamental ingredients needed for cars to drive themselves safely without human assistance.

The E/E architecture of a vehicle defines the relationship between its software, hardware and computing power. It’s well and good collecting data to advance autonomous driving systems, but without the right infrastructure in place to process that data, it can’t be analysed in real time to improve driver experience and safety. It’s clear that traditional approaches to vehicle architecture are no longer viable options as autonomous cars are becoming a reality.

A new forward-looking approach to vehicle architecture and networking is needed, which allows successive integration of innovative electronic components. In about five years, vehicles with this new E/E architecture could be driving on the road fully automated at Level 4, and at Level 5 around 2025.

The surroundings

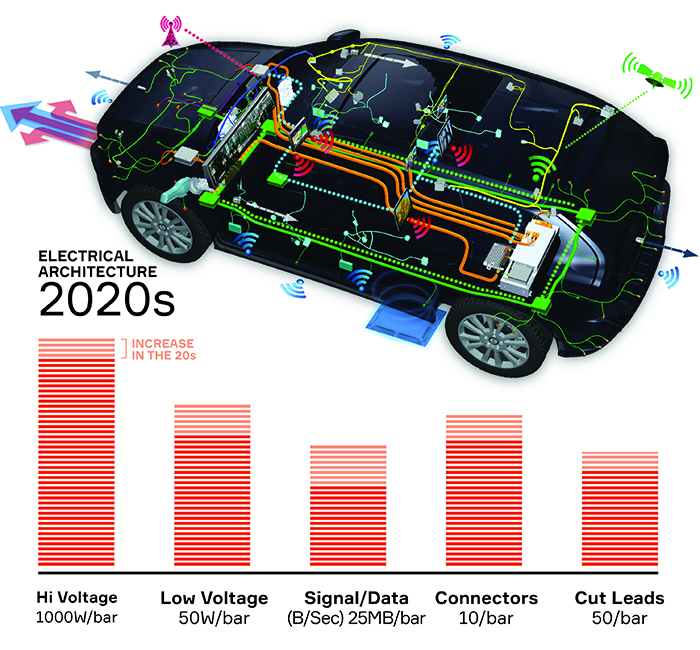

The share of electronics in automobiles will rise from 20% in 2010 to about 50% in 2030. For Level-4 vehicles, the data volume will increase tenfold compared to today’s Level 2. Driving functions’ increased automation and the electrification of the power unit – with many new and additional sensors, advanced driving functions, functional requirements and redundancies in the E/E architecture – are presenting to engineers an increasingly complex system that’s more and more difficult to control.

Until now, functional extensions in automobiles have been addressed by a linear, proportional extension of the vehicle’s electrical system. However, this simple addition of new functions and hardware components to the existing E/E architecture now reaches its limits. The wiring systems are simply becoming too heavy, too large and too expensive. Today, the E/E architecture is the third heaviest subsystem in the vehicle, following body and powertrain. In fully-equipped luxury vehicles, the wiring harness consists of over 4500 individual cables and, excluding the control units, it weighs over 50kg.

The mass and space requirements of E/E architectures can be limited by miniaturising the cables, plugs and components of the engine control unit (ECU). However, this potential has now been largely exhausted.

The growing scope of comfort functions and connectivity, as well as higher requirements of automated driving functions for redundancy and functional safety, could be met with a fully independent second power supply and signal distribution level, including sensors and processors. However, this would make the E/E architecture significantly bigger, heavier and about twice as expensive as before.

New ways of thinking required

The industry needs to meet this “architecture overload” with a completely new approach that is characterised by flexibility (standardised modular components, defined interfaces between hardware and software) and resilience (fail-operational according to ASIL D and continuous diagnostic capability). We offer a new Smart Vehicle Architecture approach, where safety is ensured by at least two batteries and power circuits, for example. Network stability can be achieved by prioritising safety-relevant data traffic. Furthermore, a multi-path topology allows data traffic to be routed to its destination via alternative paths.

This is possible through a step-by-step implementation of individual components into the existing electrical system structures, because, due to scaleability and back-blocking, a completely new architectural approach is considered unlikely by most OEMs.

In parallel, an organisational paradigm shift is recommendable: Up to now, first to be defined are the subsystems and vehicle electronics, with the necessary wiring system considered afterwards. However, a holistic definition of the E/E architecture at the beginning of development is more advantageous.

Domains instead of fragments

At the heart of this new architecture approach is a scaleable networking concept that covers various vehicle segments and automation levels, from Level 3 to 5. Its core consists of a few multi-domain computers.

An example of this is the central driver assistance controller (zFAS), developed for the Audi A8 model. In the future, powerful computing platforms like the zFAS will take over gateway functions for internal and external data traffic (connectivity and Car2X), calculations for drive management and infotainment functions. Thanks to their performance, these multi-domain computers can support each other as a fallback level for safety-relevant driving functions. These ECUs will help to contain the current proliferation of more than 100 separate ECUs and hence remove complexity from the E/E architecture. At present, consolidation to three or possibly just two central computers are not feasible due to processor power, power dissipation and the amount of data to be evaluated.

The technical prerequisites are available with modern semiconductor technologies and extremely high bandwidth data buses. Ethernet and HDBaseT with up to 10Gbit/s are just the beginning.

Another approach would be lossless pre-compression and pre-evaluation in so-called zone controllers that read sensors, collect data and also operate actuators in a decentralised manner in the vehicle. The automotive industry is currently researching such algorithms with minimal latency times for compression and decompression. Nevertheless, the race between existing bandwidth of data networks and increasing resolution of sensors, as well as the associated higher data volumes, will remain an essential characteristic of further developments in automated driving.

Multifunctional satellites

The automotive industry is already developing a completely new approach with the so-called Power Data Centers (PDC). These are zonally distributed control units, ideally in the four corners of the vehicle where the concentration of sensors for autonomous driving is very high, as is the electrical power requirement of the actuators. Two additional PDCs in the B-pillar area are conceivable for vehicles with particularly extensive equipment, such as those in the premium segment.

The PDCs distribute the power for the surrounding electronic systems, collect and distribute the many raw sensor data to the central computers, where they are processed for automated driving commands. In addition, the PDCs can perform simpler control functions such as light, trailer or audio system, helping reduce the number of comfort control units even further.

As innovative systems, the PDCs have smart fuses with diagnostic functions. Although these are somewhat more cost-intensive than conventional fuses, their diagnostic capability increases functional safety. In addition, their configurable fuse characteristics enable a significant reduction in the average line cross-section.

For example, the PDCs are capable to diagnose power supply. In general, our approach provides for two galvanically-separated batteries that can be operated with different voltages – say, 12 and 48V. Since the power is distributed to the PDCs, and from there to the individual consumers via a ring topology, the smart fuses of the PDCs can detect short circuits through a fast and precise analysis of the behaviour of the current and switch off and isolate the relevant network segment. However, this must be done so quickly that the applied voltage does not fall below the permissible value of 6V (in the 12V on-board network). To achieve this, it is important to set up a test bench with self-learning software and artificial intelligence that addresses error analyses via PDC and possible solutions.

Flexible data traffic

The data traffic between sensors, PDCs and multi-domain computers takes place with a ring topology so that power supply or data traffic is guaranteed in the event of faults and failures. Our preferred transmission technology is either HDBaseT technology (8Gbit/s) or 10Gbit/s Ethernet. In addition, the PDCs are linked to the central gateway via a star-shaped CAN-FD network so that certain functions are quickly available after the vehicle has been woken up.

In addition, our concept provides a cross-connection for the most important sensors: for example, the radar sensor on the right front can still deliver data even if the right front PDC fails, as it is connected to the power supply and data line of the left-front PDC. This sensor clustering enables enough depth of information to be maintained at every part of the vehicle. Even if a PDC fails, a vehicle can continue to “flow” in traffic in a controlled manner and stop safely – for example, to park in a car park.

In addition to diagnostic capability, intelligent safety concept and energy management, our technology can offer further features for functional safety. The zonal division and thus reduction of cable harnesses, as well as the extensive use of standard components, can significantly simplify automated production. This is also in line with the wishes of many OEMs, that not only expect a higher level of automation in wiring system production, but also higher manufacturing quality and reduced costs. Finally, the traceability of manufacturing processes and parameters is improved. However, this higher level of automation can only be achieved with the early involvement of electrical system experts in the vehicle’s development.

Smart approach to vehicle architecture

Therefore, it is possible to create a new trend in data processing. Our approach allows sensor data to be evaluated on site in order to limit data traffic in the network. New broadband transmission technologies, high-performance computers and big data now enable the opposite. A smart approach to a vehicle’s architecture allows powerful domain computers to gain a variety of insights from raw data, supporting driving, databases in the cloud or directly adjacent vehicles.

This intelligent network, consisting of power supply, data transmission and domain computers, not only offers a very high level of functional security and redundancy, but the integration of different functions on a few domain computers also reduces costs. It’s no doubt that the future of autonomous mobility hinges on a complete overhaul and re-architecture of the nervous system of a vehicle. The future will be one that will deliver a fast, safe and reliable distribution of data and power, and the automotive players to achieve this will be the ones that win the race to developing the world’s safest, fully-autonomous vehicles.