STMicroelectronics (ST) has introduced a new family of 5MP CMOS image sensors: VD1943, VB1943, VD5943, and VB5943. These advanced ST BrightSense sensors are designed to accelerate the development of innovative vision applications across industries, including advanced industrial automation with enhanced machine and robotic vision, next-generation security including biometric identification and traffic management, and smart retail applications such as inventory management and automated checkout. A longtime leader in optical sensing technology for consumer applications, ST continues to expand its offering for new applications with its industry-leading design, 3D stacking expertise and high-volume manufacturing for market-leading performance.

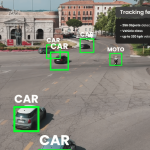

“Our new image sensors with hybrid global and rolling shutter modes allow our customers to optimize image capture, ensuring motion-artifact-free video capture and low-noise, high-detail imaging at the same time, making it ideal for high-speed automated manufacturing processes and object tracking. This architecture is unique on market today and provides unmatched flexibility, performance, and integration. We continue to broaden our portfolio of solutions for a wide range of industrial applications and want to bring the best of optical sensing technologies to both existing and new applications,” said Alexandre Balmefrezol, Executive Vice President and General Manager of STMicroelectronics’s Imaging Sub-Group.

The VD1943, VD5943, VB1943, and VB5943 sensors, part of the ST BrightSense portfolio, are ready for evaluation and sampling, with mass production scheduled to begin in February 2026.

The RGB-IR variants of the sensors feature on-chip RGB-IR separation, eliminating the need for additional components and simplifying system design. This capability supports multiple output patterns, including 5MP RGB-NIR 4×4, 5MP RGB Bayer, 1.27MP NIR subsampling, and 5MP NIR smart upscale, with independent exposure times and instant output pattern switching. This integration reduces costs while maintaining full 5MP resolution for both color and infrared imaging.

The sensors incorporate backside illumination (BSI) and capacitive deep trench isolation (CDTI) pixel technologies to enhance sensitivity and sharpness, particularly in low lighting conditions. Single-frame on-chip HDR improves detail visibility across bright and dark areas. These features enable high-quality imaging in challenging environments and support advanced machine vision and edge AI applications.

Using 2.25 µm pixel technology and advanced 3D stacking, the sensors deliver high image quality in a smaller footprint. The die size is 5.76 mm by 4.46 mm, with a package size of 10.3 mm by 8.9 mm, and an industry-leading 73%-pixel array-to-die surface ratio. This compact design enables integration into space-constrained embedded vision systems without compromising performance.

“Industrial and security imaging are pushing sensor performance to new levels, enabling functions from identification to robotic guidance, gauging and advanced monitoring and inspection,” said Florian Domengie, PhD Principal Analyst Imaging at Yole Group. “By 2030, this image sensor market is projected to reach $3.9 billion with over 500 million units shipped. Key advances will include enhanced low-light performance, on-chip intelligence, and hybrid global/rolling shutter operation, combining low noise with high-precision temporal sensing.”