You may be surprised to find a conventional 12V lead-acid battery in electric vehicles (EVs). Why does an EV need a conventional battery when there’s a 400V or 800V battery already in it to power the motors?

Today, 12V and 48V batteries power all the other systems in the vehicle, but they add cost and weight in addition to using valuable space. So, removing the 12V battery and use the 400-800V one instead should be enough to power all the systems in the car, right?

The simple answer is that many automotive systems, especially safety systems, must respond quickly to sudden changes in power, and typically batteries have much better response times than DC-DC power converters – until recently.

A fresh look

New EVs consume up to twenty times more power (from 3kW to over 50kW) than combustion engines. To date “progress” has meant adding more and higher-powered batteries to cars, but it is time to take a fresh look

A typical load in a vehicle will have two types of current draw: one for starts and one for steady-state operation. This could either be raw or existing power from which a signal is derived.

The loads that use raw power will draw a large amount of current, either to charge a capacitor or to turn an armature. After being energised (start-up), the current drops down and the load operates continuously (steady state). This initial current draw is what makes the battery a good option for legacy ICE vehicles but not EVs, where weight dramatically impacts range and performance. Thus, it makes sense to eliminate the heavy lead-acid or lithium 12V battery and replace it with a lighter, compact and high-performance DC-DC converter.

High-performance power modules

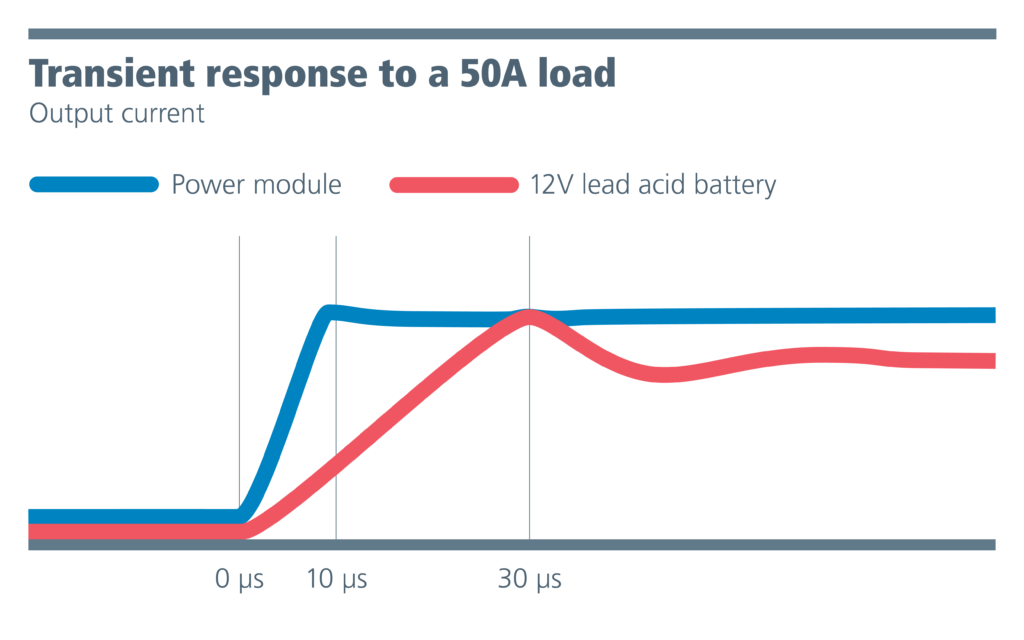

In a vehicle replacing the 12V battery with a traditional converter may cause the load voltage to drop low enough that the load turns off, causing a reboot. A key parameter to look at is the load voltage deviation during a change in current relative to time, also known as transient response. The lower the voltage deviation, the higher the system performance.

A modular power approach combined with topologies such as Vicor’s Sine Amplitude Converter (SAC) enables a much higher slew rate of a 12V lead-acid battery; see Figure 1. Using SAC can process thousands of amperes from the high-voltage battery to the load, eliminating dips or falling out of regulation.

Automobile manufacturers typically require 250A/ms for their fastest loads, which 12V batteries can achieve (75A/30µs). The Vicor modular approach provides transient response of 75A/10µs, thus creating a “virtual battery” that responds three times faster than 12V.

The SAC’s turns ratio, called K factor, is the primary-to-secondary-turns ratio. A key advantage to SAC is that any primary-side capacitance is multiplied by the K factor squared. For a 12V-to-48V conversion, the K factor is ¼, which means the effective secondary capacitance is 42, or 16 times the primary capacitance.

The Vicor NBM is an ideal converter to transfer the energy load from a mechanical source, which is on all the time, to an electrical source of energy that cycles on and off, allowing better efficiency and control. The NBM in conjunction with the SAC replicate the essential properties of a physical battery.

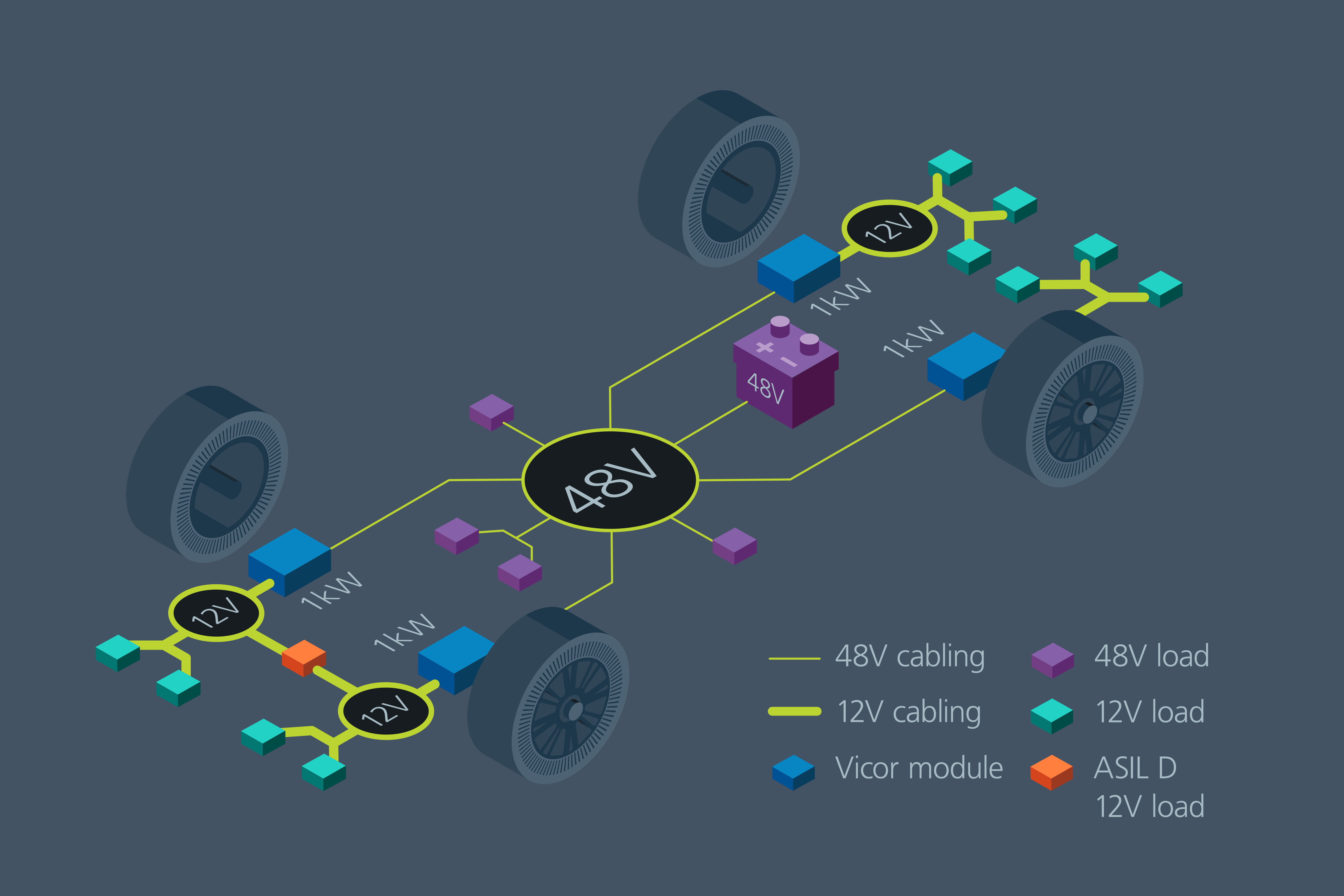

With modular approach, the power source can be split into different zones, with an NBM placed anywhere around the car – the dashboard, trunk or by wheels. Having the power source closer to the load reduces parasitic inductances and series resistances, for a higher-performing power system. The same approach also applies to HV-to-48V conversion, creating a 48V virtual battery; see Figure 2.

The largest source of energy in the vehicle is the traction motor battery, so it makes sense to use it to down-convert voltages. Typically, in an EV this is either 400V or 800V, soon to be replaced with 1,200VDC or 1,400VDC.

A modular approach can easily process 700,000A/s, and can be paralleled in an array to create a large power-processing system, with isolation from any primary bus voltages that are 60V or higher.

In theory, the NBM’s power capability only suffers due to thermal effects, but if properly cooled it can process very high amount of power. It provides the added benefit of bidirectional operation and can start up in either direction.

By Pat Kowalyk, Field Application Engineer, Vicor