Automated guided vehicles (AGVs) and autonomous mobile robots (AMRs) handle transportation processes efficiently and safely on the factory floor, materials processing premises but also warehouses and logistics centres. They ensure safe, precise and automated material handling, relieving employees or hard tasks and, even, mitigating the shortage of skilled labour. They can be largely left to their own decisions, being flexibly integrated into existing systems, making the whole industrial setup easily managed, optimised and efficient.

However, developing AGVs and AMRs systems requires hardware and software to enable their real-time processing and decision making. They also must meet stringent safety certifications.

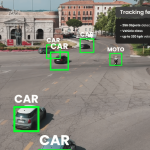

Generally, AGVs follow predefined routes using tracks and markers, whereas AMRs rely entirely on onboard sensors, real-time processing and AI to interpret their surroundings and make autonomous decisions. Both types are characterised by intelligent navigation and localisation capabilities, advanced sensor fusion and high-speed communication between components. To meet these demands, these systems require dedicated computing cores, Global Navigation Satellite System (GNSS) units and advanced network interfaces, where conventional computing architectures are out of their depth in supporting their successful operation. Edge processors handle tasks that include sensor and image processing, motion control and other computations. Information is gathered from many sensors, but also radar, LiDAR and, even, cameras, ensuring these robots’ safe movement and navigation. Inter-component communication and data transfer must be achieving with minimal latency, which requires seamless interaction between hardware, software and middleware.

Complexity, reduced!

Overall, building a mobile robot can be complex, requiring integrated, certifiable hardware and software solutions. To simplify their development, manufacturers like NXP and MicroSys Electronics provide specific platforms and tools. Future-ready hardware components such as system-on-modules (SoMs), operating systems and frameworks for real-time control ease the task. Developers are also provided with pre-validated hardware, extensive security features and optional middleware, to significantly reduce their development effort and risk. With comprehensive software integration, AGVs and AMRs benefit from greater scaleability, improved data availability and safe autonomous operation.

Pre-configured SoMs reduce design complexity by providing key components in an application-ready module. One such module well-suited for building AGVs and AMRs is the miriac MPX-S32G399A from MicroSys Electronics, with dimensions of only 82 mm x 50 mm.

High-efficiency CPU

The miriac MPX-S32G399A SoM is based on the NXP S32G399A processor, which combines ASIL-D safety with high-performance application processing, along with extensive network acceleration. The S32G3 CPU supports modern vehicle architectures such as service-type gateways, vehicle computers, domain controllers, zonal processors, safety processors, and more. According to NXP, the S32G3 vehicle network processors are supported by a broad range of software, in addition the S32 Design Studio IDE.

This SoM features eight 1.3GHz Arm Cortex-A53 cores, which can be arranged to operate in lockstep mode for enhanced reliability. Four Arm Cortex-M7cores supplement the application cores with enhanced functionality, including a Safety Package for safety-critical systems.

The NXP CPU is supported by 4GB LPDDR4 32-bit memory at 3200MT/s, 64MB QSPI Flash memory, and 32GB eMMC. The integrated Hardware Security Engine (HSE) provides secure boot functionality, and the Low Latency Communication Engine (LLCE) accelerates CAN, LIN and FlexRay message processing.

AI accelerators such as the Hailo-8 AI processor can be integrated via the onboard M.2 connector, enabling faster data processing and comprehensive sensor fusion.

To further reduce design complexity, developers can use a carrier board that, combined with the SoM, forms the single-board computer (SBC), miriac SBC-S32G399A. This includes pre-integrated software and operating systems such as Linux, VXWorks (on request) and others. The SBC provides advanced CPU interfaces for easy connectivity, but it also integrates automotive buses like FlexRay, LIN, or CAN, making it highly suitable for innovative automotive and sensor fusion applications for industrial setups.

The miriac MPX-S32G399A can be combined with the miriac MPX-S32Z2 SoM built around the NXP S32Z2 CPU, for controlling external peripherals like image sensors, LiDAR or radar in real time, and to process and analyse the recorded data.

Meeting connectivity demands

To meet the AGV and AMR communication requirements, the SBC offers a wide range of Ethernet interfaces, some with Time-Sensitive Networking (TSN) support, including a 1GbE, 1000BASE-T1, and 6x 100BASE-T1. In addition, MicroSys provides interfaces such as USB 2.0, 18x CAN-FD, 8x LIN, 2x FlexRay, GPIOs, and JTAG. The automotive-specific SJA1110 switch is also included in the comprehensive interface support.

The module can withstand harsh environments ranging from 0 to +70 °C – and from -40 to +85 °C in extended temperature ranges – significantly reducing development risks. Its modularity shortens development time and costs. Integrated security features allow compliance with industry-specific safety and regulatory standards.

Compared to an open computer-on-module standard like SMARC, MicroSys can fully leverage the performance of the NXP CPU with its proprietary standard. Not all CPU interfaces can be made externally available via SMARC, as the standard only supports certain pinouts.

In contrast, the MicroSys SoM exposes all critical interfaces – such as all Ethernet and CAN ports – enabling a scaleable number of interfaces and maximum CPU performance at the connector. It also offers optional CPU monitoring via a supervisor.

Software integration

Software also plays a critical role in AGVs and AMRs, supporting functions like navigation, object detection, route planning, even power management. For that, real-time data transmission and processing for rapid response are crucial.

Comprehensive software integration enables mobile robots to operate seamlessly, safely and efficiently, with optimal interaction between sensors, control systems, and communication interfaces. It also enhances scaleability, facilitates updates and allows quick adaptation to new processes or environments.

To ease this challenge for developers, MicroSys provides an application-ready Linux operating system on its platform. Developers can therefore fully concentrate on their application. MicroSys can also offer sup-port from qualified partners for bare-metal or QNX programming.

By Jörg Stollfuß, Field Application Engineer, MicroSys Electronics